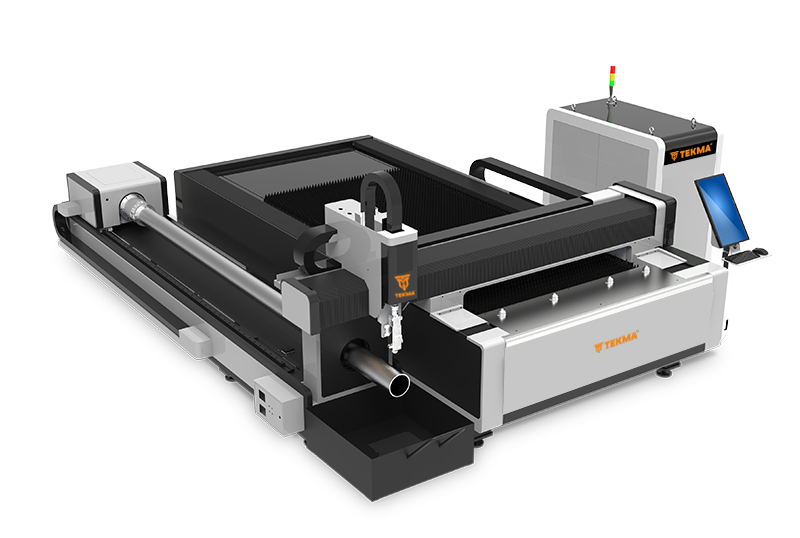

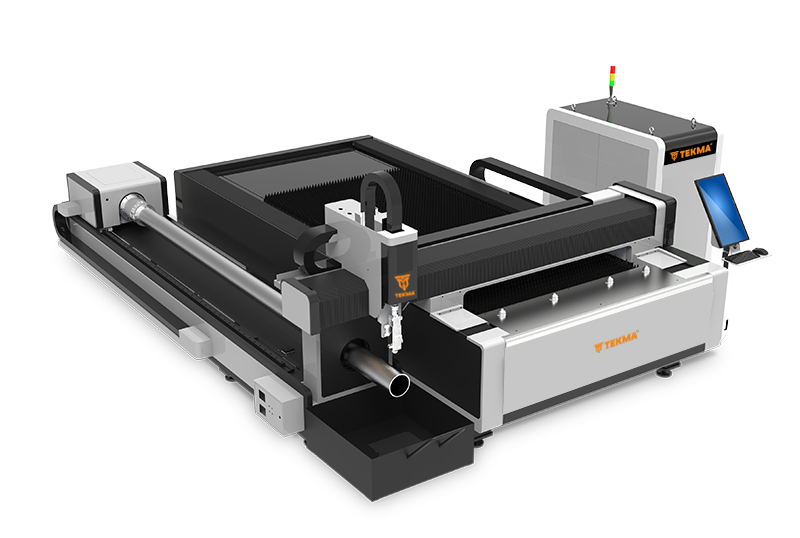

Dual Use and Cost-saving

series can be used to process plane materials and various pipes. It has multiple uses, greatly saving the floor space and improving the processing efficiency.

Automatic clamping

The front and rear are equipped with fully automatic electric and pneumatic chuck, which can clamp automatically and determine the pipe center automatically. the diagonal adjustable range is 20-200mm.

Automatic support bracket

Support different types of pipes intelligently,The problem of long pipe deformation is solved

Laser Cutting head RAYTOOLS / WSX

Industrial Machine bed

Flake graphite cast iron, the lowest tensile strength

of which is 200MPa. High carbon content, high compressive strength and high hardness. Strong shock absorption and wear resistance. Low thermal sensitivity and bed gap sensitivity reduce the loss of equipment in using.

Lifetime service

It ensures the accuracy of the machine working for a long time, and it will not deform during its lifetime use.

Higher precision

A solid bed has high stability .It is unmatched by other materials and structures. The use of graphite cast iron as a raw material keeps the precision of the machine tool for a long time and remains unchanged for 50 years. The rough, fine and super-fine of the imported gantry machining center guarantee the machining accuracy requirements of the machine body.

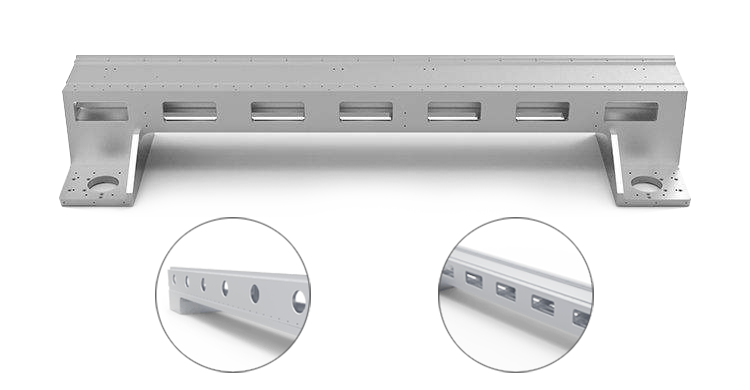

Cast aluminum beam

Monolithic cast aluminum beam,light weight, high strength, no deformation. Molded and framed by integral steel mold and die-casting technology, light crossbeam make equipment a high operation speed, improving processing efficiency and processing quality.

The light crossbeam can ensure the machine have high moving speed and improve the processing efficiency.

More efficient

The aluminum profile beam of the aerospace industry makes the equipment have efficient dynamic performance, greatly improving processing efficiency while ensuring processing quality.

Wireless remote control equipment

Magnetic design can be adsorbed on the machine bed at any time, available at all times.

It allows you to operate the machine at close range and control the machine at different angles.

TECHNICAL PARAMETERS

| Model No. | TLF-3015HT | TLF-4020HT | TLF-6020HT |

| Working Area | 3000*1500mm | 4000*2000mm | 6000*2000mm |

| Laser output power | 1000W /1500W/2000W/3000W/4000W/6000W/8000W/12000W | ||

| Repeated repositioning accuracy | ±0.03mm | ||

| Positioning accuracy | ±0.02mm | ||

| Maximum speed | 140m/min | ||

| Maximum acceleration | 1.2G | ||

What materials can be processed ?