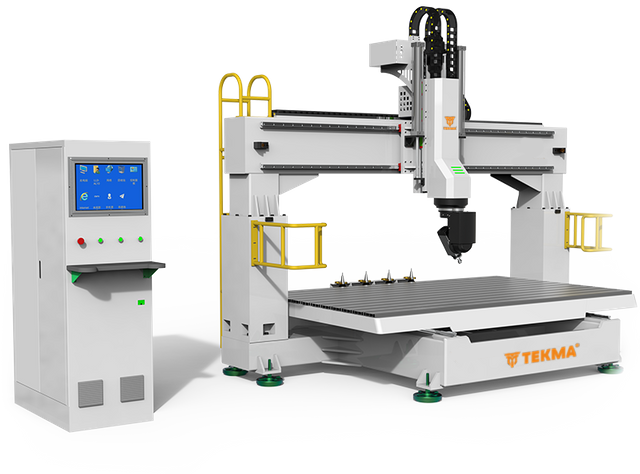

Real 5D processing

X,Y,Z,B,C 5 axis linkage, truly realize three-dimensional machining. Maximum angle attainable ±320° .It is suitable for metal, wood, foam,plastic and other materials processing, widely used in mold industry.

![]() Extreme machining stiffness thanks to the tilting B axis that generates minimum torque on the rotating axes

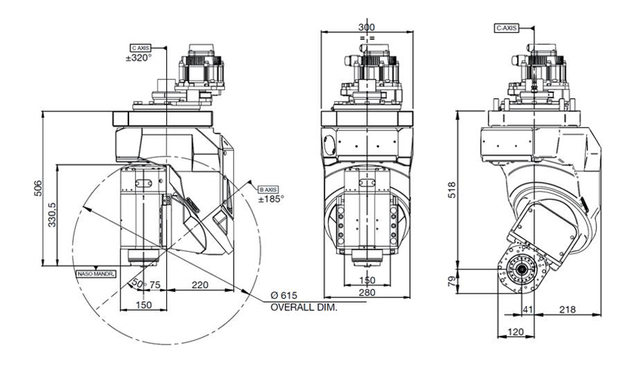

Extreme machining stiffness thanks to the tilting B axis that generates minimum torque on the rotating axes

![]() Maximum coverage of the machining areas

Maximum coverage of the machining areas

![]() Maximum coverage of the machining areas

Maximum coverage of the machining areas

![]() Wide rotation of axis C ± 320° (opt: continuous rotation) All the spindle from Italy HSD or HITECO

Wide rotation of axis C ± 320° (opt: continuous rotation) All the spindle from Italy HSD or HITECO

![]() Maximum coverage of the machining areas

Maximum coverage of the machining areas

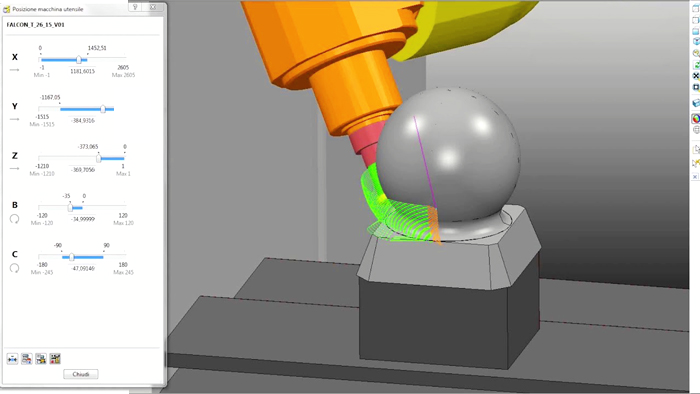

SYNTEC / LNC / OSAI smart control system

5 axis control system with RTCP(Real-Time Tool Center Point Rotatio) function. It greatly improves the machining accuracy and reduces the design difficulty.

MPG is standard configuration

Perfect compatibility with world mainstream design software

SolidWorks / UG / AlphaCAM all can be used as the design software for this machine.Choose one you are familiar with

Servo motor is standard configuration

YASKAWA/Fuji/DELTA/Leadshine servo motor multi options. Ensure high precision and stable operation of the machine

World's top quality rails and gear rack

HIWIN/THK/YYC rail and rack are available. Precision helical gear racks on the

X and Y axes. which ensure a high working speed.The precision gearbox is directly coupled to the Servo motor and pinion. This eliminates belt stretch inaccuracies assuring high-speed machining while the system positions the spindle accurately.

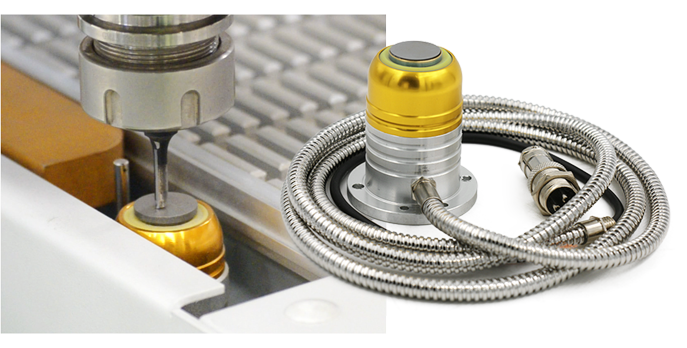

Tool sensor makes processing accuracy higher

Automatic tool calibration pad is designed for easily and accurately recording of tool length

Vacuum table makes materials more secure

vacuum plenum table surface which is very easy for fixing the materials on the table;Zones can be turned off easily via control valves on the front of the machine. Gasketing can also be routed to accommodate various material sizes and styles.

TECHNICAL PARAMETERS

MM

| Moel No. | TLR-1212-5 | TLR-1224-5 | ||

| Traveling size | 1720*1820*750mm | 1720*3040*750mm | ||

| Working size | 1220*1220*500mm | 1220*2440*500mm | ||

| Table size | 1230*1220mm | 1230*2440mm | ||

| B/C Axis | B:±185° C:±320° | |||

| Max positioning speed | B:10000°/' C:11500°/' | |||

| Max work speed | B:4500°/' C:5500°/' | |||

| Axes positioning precision | 1 arcmin | |||

| Transmission | X/Y Rack and Pinion Drive, Z Ball Screw Drive | |||

| Spindle Power | 7.5/12KW(HSD/HITECO) | |||

| Traveling Speed | 60/60/20 m/min | |||

| Working Speed | 20 m/min | |||

| Tool magazine | Carousel 8/12 Slots | |||

| Driving System | Yaskawa | |||

INCHI

| Moel No. | TLR-1212-5 | TLR-1224-5 | ||

| Traveling size | 67.7*71.6*29.5inch | 67.7*119.7*29.5inch | ||

| Working size | 48*48*19.7inch | 48*96*19.7inch | ||

| Table size | 48.4*48inch | 48.4*96inch | ||

| B/C Axis | B:±185° C:±320° | |||

| Max positioning speed | B:10000°/' C:11500°/' | |||

| Max work speed | B:4500°/' C:5500°/' | |||

| Axes positioning precision | 1 arcmin | |||

| Transmission | X/Y Rack and Pinion Drive, Z Ball Screw Drive | |||

| Spindle Power | 7.5/12KW(HSD/HITECO) | |||

| Traveling Speed | 196.8/196.8/65.6 ft/min | |||

| Working Speed | 65.6 ft/min | |||

| Tool magazine | Carousel 8/12 Slots | |||

| Driving System | Yaskawa | |||

What materials can be processed ?